Intercalation –

A Nobel in chemistry for figuring out how to do a bit less chemistry.

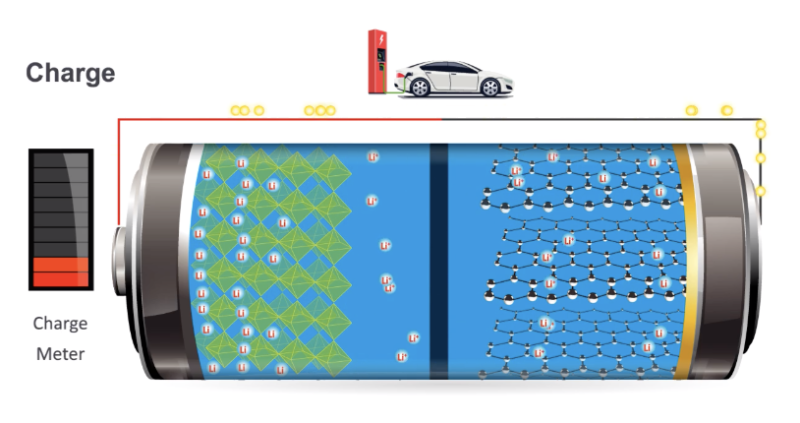

Enlarge/A diagram showing lithium ions moving between two different materials they can intercalate into.

Lithium-ion batteries have become central to everything from the mobile-electronic revolution to electric vehicles, and they’re poised to play a huge role in fostering the expansion of renewable power. It’s safe to say that their development has made a discernible impact on the modern world. But aside from the fact that they involve lithium ions, the chemistry that enables these batteries to power so many things while balancing size, durability, and weight isn’t widely understood.

Today’s Nobel Prize in Chemistry provides a fantastic opportunity to correct that, as it honors three researchers who made key contributions to the development of the lithium-ion battery: Stanley Whittingham for developing the first intercalation-driven version, John Goodenough for developing the cathodes we use today, and Akira Yoshino for developing the anodes.

Less chemistry?

The earliest batteries we developed were driven by chemical reactions. The lead-acid battery, for example, has two electrodes that undergo reactions with sulfuric acid in the electrolyte, liberating electrons to be used for other purposes. These reactions are the sorts of things you’d recognize from high school chemistry, with atoms swapping their partners and transferring electrons to end up in a different charge state. To an extent, the development of the lithium-ion battery was an attempt to get rid of all that.

Lithium has a number of advantages as a battery material. For one, it’s the lightest metal on the periodic table, with an atomic number of only three. The electron it gives up in chemical reactions is quite energetic; combined, these features make for a high energy density per weight. Unfortunately, they also make lithium quite reactive, and it will react spontaneously with both air and water. Not honored by today’s Prize was the work involved in developing electrolytes that aren’t based on water but can still remain liquid at typical operating temperatures and shuffle lithium between a battery’s cathode and anode.

Stanley Whittingham was the first to shift lithium battery development away from a lead-acid-like chemistry to something called intercalation. He and his co-workers focused on materials that have a crystal structure with vacancies that are large enough to allow a lithium atom to fit in — the process of inserting lithium into this existing structure is called “intercalation.”

Whittingham and his colleagues were able to show that materials with a specific formula — a metal with two negatively charged ions, like titanium disulfide — had two critical properties. First, they formed a layered structure that allowed the ions to enter and exit the material rapidly along the layer borders. Second, once the ion was in place, it didn’t disrupt the structure significantly. This allows for a deep charge without the structure expanding due to the new material, possibly breaking the battery’s housing.

Critically, once in place, electrons could be fed into the material, returning lithium to a neutral state. The energy that’s released during this process depends in part on the environment provided by the material that hosts the lithium. Whittingham went on to demonstrate a battery based on this chemistry at Exxon research, and John Goodenough expanded on it, finding that cobalt dioxide performed much better than titanium disulfide, improving the voltage supplied by the battery substantially.

Less metal

But there was a significant issue with these battery designs: the cathode was pure lithium metal. The presence of metallic lithium created a chemical hazard if the battery were ever broken open, and it tended to have bad performance over multiple charge / discharge cycles. To begin with, the volume of lithium invariably shrunk as the anode material shuttled off to intercalate at the cathode, which put mechanical stress on the battery. And when the lithium returned, it didn’t spread evenly across the anode. Instead, it tended to form spikes on the surface, which could possibly break through the membrane separating the anode and cathode, shorting out a cell of the battery.

People had been experimenting with carbon-based intercalation materials for anodes for a while, but the results suffered from mechanical problems, as layers tended to flake off during charge / discharge cycles. Akira Yoshino helped develop anode materials that were a mix of graphite layers for intercalation and a more heavily interlinked form of carbon that held the whole thing together in a battery. Yoshino’s work started in 1985; by 1991, the first lithium-ion battery reached the market.

Since then, Goodenough’s team has continued to develop cathode materials, including some that can handle high charge rates. And a large group of researchers and commercial companies has contributed developments in anode, cathode, and electrolyte materials, making huge strides in the energy density of batteries.

Intriguingly, however, lithium-battery developments appear to be looking back to the future. One of the two major areas of research now is in lithium-air batteries, in which lithium would give up its electrons in order to undergo a chemical reaction with oxygen, rather than intercalating. And other researchers are working on lithium metal anodes, trying to find ways to ensure that the lithium is deposited smoothly on the anodes’ surface instead of forming spines. Either of these projects would increase the energy density further by getting rid of some of the materials that normally occupy space at the electrodes.

It’s fair to say that lithium batteries have already dramatically changed how we handle energy, even if these improvements never come to pass. So now’s not a bad point to honor the people who played key roles in getting us here.

GIPHY App Key not set. Please check settings