On the Twelfth Day of Christmas –

New method based on double-curvature effect described by Gauss nearly years ago.

**************************

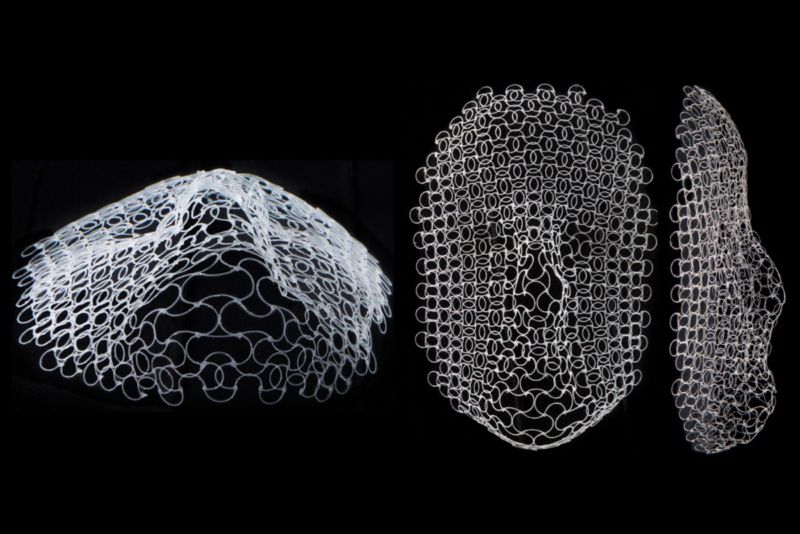

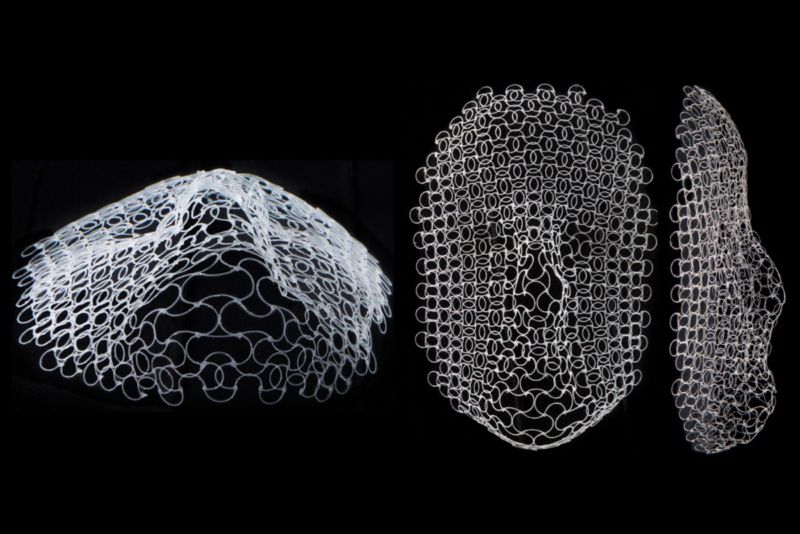

The next big thing in 3D printing just might be so-called ” 4D materials“which employ the same manufacturing techniques, but are designed to deform over time in response to changes in the environment, like humidity and temperature. They’re also sometimes known as active origami or shape-morphing systems. MIT scientists successfully created flat structures that can transform into much more complicated structures than had previously been achieved, including a human face. Theypublished their resultslast fall in the Proceedings of the National Academy of Sciences.

Prior researchers had successfully come up with ways to get such materials to shape-shift into simple structures. MIT mechanical engineer Wim van Rees, a co-author of the PNAS paper, devised a theoretical method to turn a thin flat sheet into more complex shapes, like spheres, domes, or a human face. “My goal was to start with a complex 3-D shape that we want to achieve, like a human face, and then ask, ‘How do we program a material so it gets there?'” he said. “That’s a problem of inverse design.” But his original simulations were for an idealized sheet of material with no boundaries on how much it could expand or contract, and most real-world materials do have limits. It’s a problem of “double curvature,” first described by (th century mathematician) *********************** Carl Friedrich Gauss.

But his original simulations were for an idealized sheet of material with no boundaries on how much it could expand or contract, and most real-world materials do have limits. It’s a problem of “double curvature,” first described by (th century mathematician) *********************** Carl Friedrich Gauss.

****************************** Enlarge************************ /A set of lattice structures that has transformed into spherical caps, or dome-like shapes, after application of a temperature difference.J. William Boley

****************************** Enlarge************************ /A set of lattice structures that has transformed into spherical caps, or dome-like shapes, after application of a temperature difference.J. William BoleyThey designed the ribs to grow at different rates across the mesh sheet, each one able to bend sufficiently to take on the shape of a nose or an eye socket. The printed lattice was cured in a hot oven, and then cooled to room temperature in a saltwater bath. And voila! It morphed into a human face. The team also made a lattice containing conductive liquid metal that transformed into an active antenna, with a resonance frequency that changes as it deforms.

These kinds of shape-shifting materials might one day be used to make tents that can unfold and inflate on their own, just by changing the temperature (or other ambient conditions). Other potential uses include deformable telescope lenses, stents, scaffolding for artificial tissue, and soft robotics.

GIPHY App Key not set. Please check settings