Brewing fuel –

Systems-level engineering of a living thing is remarkably complicated.

John Timmer – Jan 24, : 0409 pm UTC

A little while ago, we covered the idea of using photovoltaic materials to drive enzymatic reactions in order to produce specific chemicals. The concept is being considered mostly because doing the same reaction in a cell is often horribly inefficient because everything else in the cell is trying to regulate the enzymes, trying to use the products, trying to convert the byproducts into something toxic, or up to something even more annoying. But in many cases, these reactions rely on chemicals that are only made by cells, leaving some researchers to suspect it still might be easier to use living things in the end.

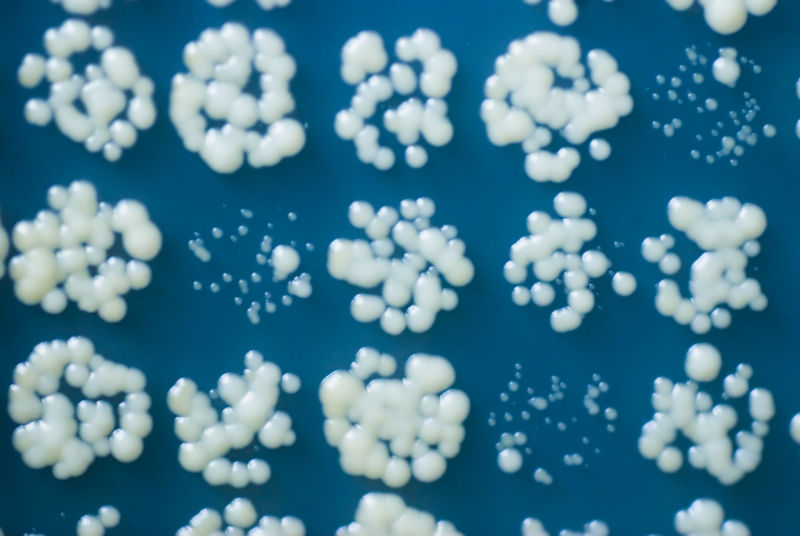

Combined, all these changes should produce more short-chain hydrocarbons in the yeast cell. And they do — but not a lot more. This was a surprise because, as noted above, these molecules are toxic to the cell. Since we don’t understand why, there was no way of directly engineering tolerance to them. Instead, the researchers simply grew yeast strains in high levels of short-chain molecules for multiple generation, allowing evolution to select one that tolerated them better. The researchers sequenced the genomes of multiple evolved strains and identified two key mutations.

Separately, they started with a protein that yeast use to pump toxins outside the cell, and sent that through two rounds of mutation and selection, looking for looking for version that more efficiently ejected the hydrocarbon molecules they were producing. The results of the two separate bits of directed evolution were combined in the yeast strain being used. Production went up a bit more.

Of course, from the cell’s perspective, all these short hydrocarbons floating around are mistakes — biochemical dead ends. So it’s not a surprise that cells also have enzymes that re-attach them to the linker that allows the synthesis enzymes to re-engage with them. These enzymes had to be deleted as well, allowing the levels of production to climb a bit more. Protect the hydrocarbons

Read More) (

)

)

GIPHY App Key not set. Please check settings